Hello all,

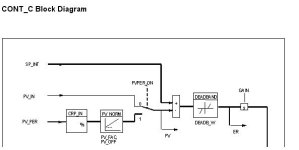

I am an electrical engineering student working on a senior design project with an industry sponsor. We are automating a burst test chamber and are completely new to plc programming. We are using siemens step 7. Trying to use a pid control function to ramp the pressure up inside a hydraulic hose following an exponential or linear setpoint curve. I am having trouble figuring out exactly how to configure this fb41 correctly for a changing setpoint. I have a basic understanding of all the different parameter of the function block, just don't know how to use them correctly apparently. Any help would be awesome. Thanks

I am an electrical engineering student working on a senior design project with an industry sponsor. We are automating a burst test chamber and are completely new to plc programming. We are using siemens step 7. Trying to use a pid control function to ramp the pressure up inside a hydraulic hose following an exponential or linear setpoint curve. I am having trouble figuring out exactly how to configure this fb41 correctly for a changing setpoint. I have a basic understanding of all the different parameter of the function block, just don't know how to use them correctly apparently. Any help would be awesome. Thanks