owusuappiah21

Member

hello,

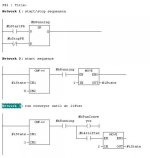

I am writing a program to run a recycle machine using simatic step 7 300.

The sequence is such that at any point in time when a stop button is pressed the system stops but the sequence should continue from where it stopped when start button is pressed.can somebody help me to code such logic?

Moreover,i would like to know how best to connect an emergency stop and light safety curtain.

Thank you

I am writing a program to run a recycle machine using simatic step 7 300.

The sequence is such that at any point in time when a stop button is pressed the system stops but the sequence should continue from where it stopped when start button is pressed.can somebody help me to code such logic?

Moreover,i would like to know how best to connect an emergency stop and light safety curtain.

Thank you