Hello everyone, I have a project that I have to do, and it sounds like this.

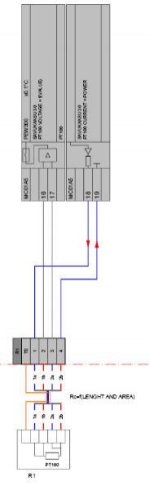

I have to connect a PT 100 sensor to a plc, and write a program that will calculate after measurement, that the sensor is between its error limits, and maybe store the measurement data, so many sensors could be measured and tested.

Also I would appreciate if someone came and explained the steps in a very basic manner, I'm new to all this.

Thanx in advance.

I have to connect a PT 100 sensor to a plc, and write a program that will calculate after measurement, that the sensor is between its error limits, and maybe store the measurement data, so many sensors could be measured and tested.

Also I would appreciate if someone came and explained the steps in a very basic manner, I'm new to all this.

Thanx in advance.