Hello all,

Sorry if my doubt is too basic.

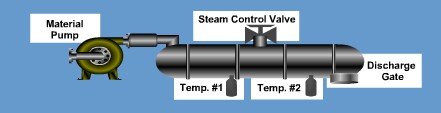

I have a material heater. Cold material enters the heater and hot material comes out (too obvious? ). A steam valve heats the material, opening from 0% to 100%.

). A steam valve heats the material, opening from 0% to 100%.

As a reference, the output temperature set point is around 280ºF. The middle temperature usually is around 260ºF.

There's one temperature sensor at the middle of the heater (half way in the heater) and one at the output

I have a Master-Slave PID cascade loop to control the output material temperature. The Master PID has the output temperature as the process variable and the middle temperature slave PID set point as the manipulated variable. The Slave PID has the middle temperature as the process variable, and the steam valve as the manipulated variable.

OK. I set the output range for the Slave PID from 0%-100%. Very straightforward.

Since the temperature sensors range is 0ºF - 300ºF, I originally set the output range for the Master PID (after scaling) from 0ºF - 300ºF. However, it seems this is not the correct approach. Sometimes the Slave SP was calculated as low as 0ºF (when the output temperature is 290ºF or more), sometimes as high as 300ºF (when the output temperature is 270ºF or less). I would expect the middle temperature set point to be in the 250ºF - 270ºF range. I changed the Master output range (when scaling, not the CV parameter in RSLogix) to restrict the middle temperature SP to the 250ºF - 270ºF range, and the system improved.

My question is, how do you estimate the Master PID output range? I mean, imagine if I had a 0ºF - 400ºF sensor range, it would be crazy to let the system go up to 400ºF in the middle.

Thank you!

Sorry if my doubt is too basic.

I have a material heater. Cold material enters the heater and hot material comes out (too obvious?

As a reference, the output temperature set point is around 280ºF. The middle temperature usually is around 260ºF.

There's one temperature sensor at the middle of the heater (half way in the heater) and one at the output

I have a Master-Slave PID cascade loop to control the output material temperature. The Master PID has the output temperature as the process variable and the middle temperature slave PID set point as the manipulated variable. The Slave PID has the middle temperature as the process variable, and the steam valve as the manipulated variable.

OK. I set the output range for the Slave PID from 0%-100%. Very straightforward.

Since the temperature sensors range is 0ºF - 300ºF, I originally set the output range for the Master PID (after scaling) from 0ºF - 300ºF. However, it seems this is not the correct approach. Sometimes the Slave SP was calculated as low as 0ºF (when the output temperature is 290ºF or more), sometimes as high as 300ºF (when the output temperature is 270ºF or less). I would expect the middle temperature set point to be in the 250ºF - 270ºF range. I changed the Master output range (when scaling, not the CV parameter in RSLogix) to restrict the middle temperature SP to the 250ºF - 270ºF range, and the system improved.

My question is, how do you estimate the Master PID output range? I mean, imagine if I had a 0ºF - 400ºF sensor range, it would be crazy to let the system go up to 400ºF in the middle.

Thank you!