jgauthier

Member

Greetings! I am very new to PLC programming and ladder logic, but I have some years of experience programming.

I thought I understood OTL, and that latching an output sets the bit high until it's unlatched. But in a program I wrote that does not seem to be the case.

So, I simplified it down, and was able to reproduce it.

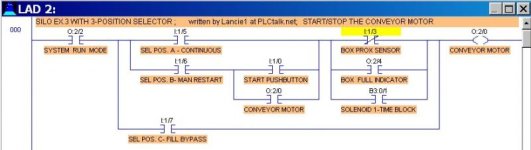

Here is the diagram:

A,B,C are exclusive. They cannot be on at the same time.

When I turn "A" on, the motor is energized.

When I turn "B" on, the motor is energized with latch.

However, when I switch to "C" from "B" the motor stops.

I'm confused about why, because I thought the latch would hold.

For those who have used LogixPro 500, this simulation can be executed in the Silo exercise.

Thanks! I appreciate the help in understanding.

I thought I understood OTL, and that latching an output sets the bit high until it's unlatched. But in a program I wrote that does not seem to be the case.

So, I simplified it down, and was able to reproduce it.

Here is the diagram:

A,B,C are exclusive. They cannot be on at the same time.

When I turn "A" on, the motor is energized.

When I turn "B" on, the motor is energized with latch.

However, when I switch to "C" from "B" the motor stops.

I'm confused about why, because I thought the latch would hold.

For those who have used LogixPro 500, this simulation can be executed in the Silo exercise.

Thanks! I appreciate the help in understanding.