How accurate are the timers in a CompactLogix L16ER ?

There are also two Point I/O cards attached: one analog two channel input and one analog 4 channel output... do these affect scan times or timer accuracy?

I would think the timing accuracy would be affected by scan times... is that right?

how can I calculate the scan time? If you were to somehow involve the PLC in a routine that took 10 seconds, would any of the timers with shorter presets fire during that time?

what kinds of things is it dependent upon? Is the WallClock more accurate?

I am measuring the lengths of objects passing on a conveyor in front of a photocell ... same thing with laser measurements taken of the thickness... some times it seems to nail them... other times ... not so much.

these measurements are not that critical... If I could measure within a 1/16" I'd be tickled ... it's not like I need to measure to the thousandth the belt is moving probably 15 -20 inch per second

typing that down here makes me think I need to pick up the calculator ..... see you in a bit

Im back ... would that mean these timers have to be accurate within 3 mSec? to get within 1/16" at 20 inches per second?

what kinds of things could be done to try to get the best accuracy possible? For example, there are routines that don't need to do anything unless the operator interacts... would it be useful to jump these routines if the operator is not interacting?

thank you

There are also two Point I/O cards attached: one analog two channel input and one analog 4 channel output... do these affect scan times or timer accuracy?

I would think the timing accuracy would be affected by scan times... is that right?

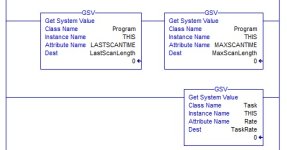

how can I calculate the scan time? If you were to somehow involve the PLC in a routine that took 10 seconds, would any of the timers with shorter presets fire during that time?

what kinds of things is it dependent upon? Is the WallClock more accurate?

I am measuring the lengths of objects passing on a conveyor in front of a photocell ... same thing with laser measurements taken of the thickness... some times it seems to nail them... other times ... not so much.

these measurements are not that critical... If I could measure within a 1/16" I'd be tickled ... it's not like I need to measure to the thousandth the belt is moving probably 15 -20 inch per second

typing that down here makes me think I need to pick up the calculator ..... see you in a bit

Im back ... would that mean these timers have to be accurate within 3 mSec? to get within 1/16" at 20 inches per second?

what kinds of things could be done to try to get the best accuracy possible? For example, there are routines that don't need to do anything unless the operator interacts... would it be useful to jump these routines if the operator is not interacting?

thank you

Last edited: