Futaba kai

Member

Hello all.

Firstly i'm new to posting on here (i've been viewing this site for over a year just never posted).

I was hoping you guys could help me with a piece of code i'm trying to make.

At the back of the shop floor robotic cells parts are dropped off which break a beam sensor then move along on a conveyor to the end of line checking members.

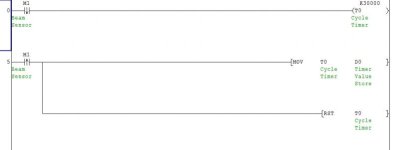

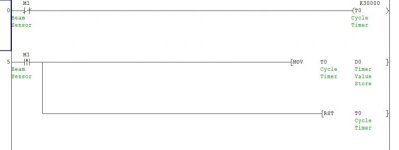

I would like to make a piece of code that gives me the cycle time of the parts going through the cell using this beam sensor e.g. every time a part is made what is the space of time between the last part dropped and the part just dropped.

Is there a way to snapshot a T, Timer then reset it? or any other way to do this?

Thanks a ton for the help I'm currently manually timing the parts by standing at the back with a stop watch and its got a PLC which could easily do this for me for all 20 odd Cells...

Firstly i'm new to posting on here (i've been viewing this site for over a year just never posted).

I was hoping you guys could help me with a piece of code i'm trying to make.

At the back of the shop floor robotic cells parts are dropped off which break a beam sensor then move along on a conveyor to the end of line checking members.

I would like to make a piece of code that gives me the cycle time of the parts going through the cell using this beam sensor e.g. every time a part is made what is the space of time between the last part dropped and the part just dropped.

Is there a way to snapshot a T, Timer then reset it? or any other way to do this?

Thanks a ton for the help I'm currently manually timing the parts by standing at the back with a stop watch and its got a PLC which could easily do this for me for all 20 odd Cells...