Hello! Wonder if you gents can establish some light on this intermittent fault we are having.

Basically we have a hoist, this hoist starts at the bottom in which it will trigger a proxy, this then inputs a 0 value in turn ''homing'' it. We then move a -65mm value in as a offset due to it lifting from a conveyor. So the hoist is sat at a value of -65mm before any movement.

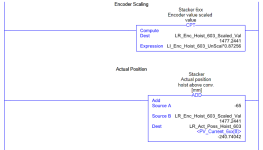

Now the drive motor is fitted with two proxy cells (BI6U-M18) triggered via 6 plates on the motor fan, this is then wired back into a 1756-HSC/A card. So are readings are -65mm to 1414mm for its motion of travel.

Now here is the issue! Every so often, when the hoist is sat in it's down position, it'll be sat reading -65mm due to the above, but suddenly the value will just drop, in the example provided down to -240mm with no activity at all. Now what do you gents think would cause this? There is no physical movement in the hoist at all, so not suspecting the brake failing on the motor or hoist dropping. We thought maybe the card itself? We are using another hoist machine off the same counter card however and that's reading fine so suspecting maybe its a faulty channel for this hoist in particular if at all possible? Also we have only a 1756-HSC/B card, many issues with swapping this from a series A?

Thanks in advance, any input is much appreciated

Basically we have a hoist, this hoist starts at the bottom in which it will trigger a proxy, this then inputs a 0 value in turn ''homing'' it. We then move a -65mm value in as a offset due to it lifting from a conveyor. So the hoist is sat at a value of -65mm before any movement.

Now the drive motor is fitted with two proxy cells (BI6U-M18) triggered via 6 plates on the motor fan, this is then wired back into a 1756-HSC/A card. So are readings are -65mm to 1414mm for its motion of travel.

Now here is the issue! Every so often, when the hoist is sat in it's down position, it'll be sat reading -65mm due to the above, but suddenly the value will just drop, in the example provided down to -240mm with no activity at all. Now what do you gents think would cause this? There is no physical movement in the hoist at all, so not suspecting the brake failing on the motor or hoist dropping. We thought maybe the card itself? We are using another hoist machine off the same counter card however and that's reading fine so suspecting maybe its a faulty channel for this hoist in particular if at all possible? Also we have only a 1756-HSC/B card, many issues with swapping this from a series A?

Thanks in advance, any input is much appreciated