That sounds like an ordinary and expected result of powering off the servo motors, especially on a system with no brakes at the motor shaft or in the power transmission mechanism.

The servos are not "losing absolute position"; they are correctly detecting the change in absolute position even when powered down.

If you need a mechanism to minimize its motion while the servos are switched off, you need clamps or brakes. Or, you need a machine alignment or homing motion sequence to re-align the system before starting up again.

Yes, it keeps up the position changes (almost) but it seems it doesnt follow it perfectly.

The issue is that the position after power down is not physically correct. I'm getting an offset when starting up and running again, we are using Absolute to not have to home it every time, but in the past I have never used absolute encoders this way.

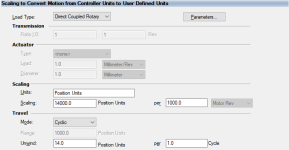

If I'm losing a (10) or 0.01 without scaling of position units we suffer consequences in the recipe when running. This is why this is an issue. Since we havnt seen this issue previously it feels these motors should be able to handle it as well. But it might just be that Older motors without the Single Cable Power/Encoder just handled it better and the Single Cable for these motors isnt as efficient in following exact position during a shutdown for some reason. (photo of scaling below)

Also, the catalog number from the axis properties is not the entire catalog number of the motor. There is more after the "P", which tells whether there is a brake or not. Something like P*12 or P*14 (2 means no brake, 4 means brake).

Yeah you're right Sorry. "VPL-B1002M-PK12AA"

VP = Permanent magnet rotary servo motors optimized to the ratings of Kinetix 5500 and Kinetix 5700 servo drives.

L = Low Inertia

100 = 100 mm

2 = Magnet Stack Length

M= 6000 rpm

P = 18-bit absolute multi-turn (4096 revolutions) digital encoder (Hiperface DSL protocol)

K = Smooth shaft

1 = Single SpeedTec DIN connector, right angle, 325° rotatable

2 = No Brake

A = IEC metric, free mounting holes (type FF)

A = Standard

https://literature.rockwellautomation.com/idc/groups/literature/documents/in/vpl-in001_-en-p.pdf - Page 2

Let me say up front that I don't have any hands-on experience with that model of Kinetix servo.

To me, absolute actual position requires an absolute encoder. If the axis moves when power is removed, an absolute encoder will power back up with the actual position, taking into account the distance moved while power was off. From the description it sounds like the axis powers back up with a discrepancy between the physical position and the position indicated by the encoder. Are you trying to operate with an incremental encoder?

The encoder is built-in inside the Motor itself as an absolute encoder.

The encoder is working as "intended" that way and the position is remembed during power off. But Im still getting a random offset of the old physical position.

I maybe wrong here, but what I think is going on is that the OP is using incremental moves rather than absolute moves. So when their system is commanded to position 123 and power is removed during movement, the system doesn't end up at position 123. In stead, maybe it ends up at 124. So when motion resumes, the systems is always off by 1. OP, correct me if I'm wrong.

In the recipe im using a CAM control. with 6-10 positions. I believe this function will automatically increment between the cam positions?

Also. During these power off tests machine was completly still and doing NO movements

I'm not sure that this matters but are the axes configured as position mode axes? Also, what firmware are you running in the plc? I don't know of any specific firmware related issues with position but someone might.

I was told by our local Rockwell distributor that a motor with absolute feedback will maintain absolute position when powered off as long as the motor is not rotated more than half of the absolute position revolutions when it is powered down. There are also issues when a plc program saved BEFORE the latest axis home is downloaded but that doesn't seem to be the case here.

Keith

Axis are configued as position mode.

Firmwares are:

Studio 5000: 33.13

2198-DO12-ERS3: 13.005

"There are also issues when a plc program saved BEFORE the latest axis home is downloaded but that doesn't seem to be the case here." - This will help another issue I've seen probably thank you.

Edit 1: We are using Absolute Encoders to not have to home the motors every time. and We have never seen this issue with older kinetix 6000. We are currently in the phase of upgrading to 5700 ERS3/4 and Tuning might not be perfect either if this can cause issues. with gains and such.

Edit 2: Motor Information

Edit 3: More Info

Edit 4: Photo.