Actually three sets, and when I wrote that are equivalent, I should have qualified that with "to within a few percent." I went over most of them by eye i.e. to the nearest digit and a half, and I did not see any significant differences*. To be fair I am getting prone to mental math errors when I try to move too quickly (just missed running into the closed half of a gate on bike ride along the Erie Canal today; phew!).

* e.g. For

υ2,

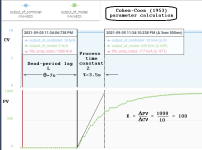

- C-C (1953): υ2 = 1.03 + 0.35μ

- An image seen in two random YouTubes: υ2 = 1 + 0.3333μ

- Image from Opticontrols.com website: υ2 = 1.03 + 0.352μ

So yes, they are different, but not enough to be bothered about in the current context.

Which is to say it is identical to just about every other thread on the forum LOL.

That can be true for someone seeking to squeeze every nickel out of their process, for which they have three or four digits of accuracy and precision in the measurement. But perfect can be the enemy of good enough.

However, as you note we know virtually nothing about the OP's process for this thread, and for many processes, the difference between Z-N/C-C-derived results and those of better methods is down in the noise and therefore not worth the time. As you say, and as my brother reminded me last night, the job is often more about business i.e. value, than engineering.

As an example, say we are doing a commissioning and need to get a control loop working to start up the plant and make product. Is it better to

- have Paul apply Z-N, get it "close enough" now, and move to the next thing to get the plant started sooner, and then have Peter come in later to optimize the tuning later

- OR

- have Peter spend the time now to optimize the tuning, but have that delay the eventual startup?

Of course, if the better tuning can be done quickly then of course it would be better to do it that way, but one of the benefits of Z-N is someone can memorize the approach and learn when it is useful, and more importantly when it is not.