sparkytex

Lifetime Supporting Member

Hello all,

here's what I'm trying to do. we have evaporators that evaporate the water from the liquor created from digesting pulp. There's 8 evaporators altogether working from 8 (start of the line where the liquor is pumped into) ending in 1. #8 has the most vacuum and the liquor is the thinnest at this stage as there's lots of water in it. We just installed a new motor with a VFD to work with a PID control to control pressure in the header to the evaps so there's a constant pressure which insures constant flow of liquor. I have this tuned and it works great holding its set point in auto at 40 PSI.

However we discovered that #8 body level transmitter isn't quite the best style of transmitter for the application. The body levels work off their own PID control with level and a control valve, I.E. level high close valve that controls liquor flow to the body and vice versa. This loop has been all over the place for years and no one has been able to tune it. I found out with a trend that if I put the PID into manual with 30% open on the valve the level in the sight glass on the body does not move at all (perfect level control with 40 PSI header pressure) however the level transmitter is still bouncing around like crazy saying its dropping 15% level in a matter of seconds. This is obviously inaccurate as I can see the level is perfect through the sight glass. No wonder why this cant be tuned properly because the PID is always chasing a false reading.

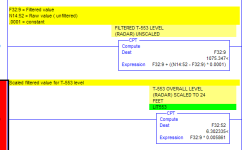

What I was thinking of doing was created an average of the Process variable (level in #8) and using that as the new process variable for the PID control so its not bouncing all over the place trying to satisfy a constant fluctuating false reading. I'm using RSLogix 5 on a PLC 5 and I remember you can use an FAL instruction to get averages. Can someone guide me through this or suggest an alternate way to get an running average of about 30 seconds from the level transmitter.

thanks, TEX

here's what I'm trying to do. we have evaporators that evaporate the water from the liquor created from digesting pulp. There's 8 evaporators altogether working from 8 (start of the line where the liquor is pumped into) ending in 1. #8 has the most vacuum and the liquor is the thinnest at this stage as there's lots of water in it. We just installed a new motor with a VFD to work with a PID control to control pressure in the header to the evaps so there's a constant pressure which insures constant flow of liquor. I have this tuned and it works great holding its set point in auto at 40 PSI.

However we discovered that #8 body level transmitter isn't quite the best style of transmitter for the application. The body levels work off their own PID control with level and a control valve, I.E. level high close valve that controls liquor flow to the body and vice versa. This loop has been all over the place for years and no one has been able to tune it. I found out with a trend that if I put the PID into manual with 30% open on the valve the level in the sight glass on the body does not move at all (perfect level control with 40 PSI header pressure) however the level transmitter is still bouncing around like crazy saying its dropping 15% level in a matter of seconds. This is obviously inaccurate as I can see the level is perfect through the sight glass. No wonder why this cant be tuned properly because the PID is always chasing a false reading.

What I was thinking of doing was created an average of the Process variable (level in #8) and using that as the new process variable for the PID control so its not bouncing all over the place trying to satisfy a constant fluctuating false reading. I'm using RSLogix 5 on a PLC 5 and I remember you can use an FAL instruction to get averages. Can someone guide me through this or suggest an alternate way to get an running average of about 30 seconds from the level transmitter.

thanks, TEX