Hi guys,

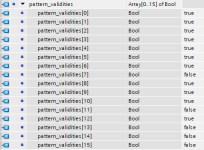

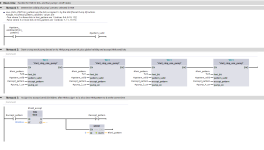

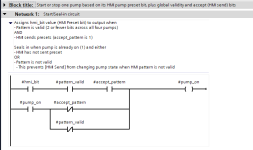

I am using CCW with AB Micro-Controller. The user can select 2 pumps out of 4 to be running. However, the user shall not be able to select more than 2 pumps and an error message should appear if the user tries to select the 3rd pump telling him "Not more than 2 pumps to run, deselect one of the pumps if you require to select another pump".

Please help me to do this as I don't know how to restrict the selection in the HMI, or shall it be done via PLC program?

Best Regards

I am using CCW with AB Micro-Controller. The user can select 2 pumps out of 4 to be running. However, the user shall not be able to select more than 2 pumps and an error message should appear if the user tries to select the 3rd pump telling him "Not more than 2 pumps to run, deselect one of the pumps if you require to select another pump".

Please help me to do this as I don't know how to restrict the selection in the HMI, or shall it be done via PLC program?

Best Regards

Last edited: