Good Morning ,

We had a 3 phase motor go bad yesterday . The motor had no nameplate .

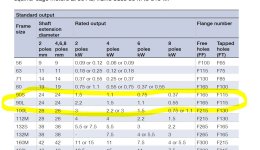

How can you determine what RPM ( or how many poles ) without a nameplate .

Any links or videos ? Good teachable moment yesterday.

Thanks so much in advance .

We had a 3 phase motor go bad yesterday . The motor had no nameplate .

How can you determine what RPM ( or how many poles ) without a nameplate .

Any links or videos ? Good teachable moment yesterday.

Thanks so much in advance .