You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Ideas for safety barrier between 2 movable parts of a machine

- Thread starter jayrod7387

- Start date

OkiePC

Lifetime Supporting Member

Looks a lot like a machine I worked with in a tire factory. They used a cage with some sections on wheels and a couple of pivot points. There was a "man-door" with a safety switch. It was simple and effective.

CaspianSage

Member

Most of the places where safety barriers are required that I have seen use a physical barrier with a switch in the e-stop circuit. They are switches specifically designed for the purpose. Allen Bradley, and others make them.

Barriers are often made with expanded metal welded to an angle iron-frame. Some are mounted with hinges so they can swing open, others are bolted up. In the United States, there are federal OSHA rules for barriers so I suggest you get someone involved in this familiar with the requirements.

Barriers are often made with expanded metal welded to an angle iron-frame. Some are mounted with hinges so they can swing open, others are bolted up. In the United States, there are federal OSHA rules for barriers so I suggest you get someone involved in this familiar with the requirements.

A steel cable and this:

http://download.schneider-electric....5633551&p_File_Name=DIA4ED2151201EN (web).pdf

using an NC + NC model can be inserted into the general emergency stop circuit

http://download.schneider-electric....5633551&p_File_Name=DIA4ED2151201EN (web).pdf

using an NC + NC model can be inserted into the general emergency stop circuit

Last edited:

jstolaruk

Lifetime Supporting Member

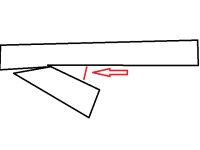

I have a few machines that need a safety barrier between 2 movable parts of a machine. The angle changes and the gap opens up from 10 ft to 14ft.

See attached photo, yes i am an artist....

With the changing distance, a light curtain would be the first choice I would look into. You could hard fence the first 10 feet.

CaspianSage

Member

With the changing distance, a light curtain would be the first choice I would look into. You could hard fence the first 10 feet.

A light fence is a great idea, I have seen those used quite a bit. The cable idea is nice but won't pass the specs if anyone can crawl over or under it.

They have gotten to the point of ridiculous in some instances as to the requirements.

A light fence provides a lot of flexibility so can be easily moved to accommodate changes.

CaspianSage

Member

If the the light fence is mounted on a moveable part of the machine it may create a challenge to keeping it aligned.

jstolaruk

Lifetime Supporting Member

They have gotten to the point of ridiculous in some instances as to the requirements.

Yeah, but I've been in a plant twice when someone was killed by equipment; one by a robot the other by a press. So I understand where management tends to go what seems like extremes.

CaspianSage

Member

Yeah, but I've been in a plant twice when someone was killed by equipment; one by a robot the other by a press. So I understand where management tends to go what seems like extremes.

Yes , -- Those safety nuts really do keep us safe. I used to have to put on a safety harness to change a light bulb in a coolant recovery system that was pretty much open air but since I had to go down into the pit it was considered a confined space... When I quit working for them I ,... to their surprise, thanked them for keeping me safe even though it made my job unnecessarily difficult at times.

It took an hour or more and Yep Three people to change that light bulb.

1. Get a Confined Space entry Permit.

2. Get an Air Sample

3. Put on a very cumbersome safety harness.

3. Get someone big enough to hull me out with the rope attached to my harness if I was overcome by contaminated air.

4 get someone to act as A safety watch.

The pit was only 5 ft deep, about 10' wide x 20' long.

Who knows what they would have done if I actually passed out and got hung up on something preventing them from dragging me out.....

CaspianSage

Member

Yeah, but I've been in a plant twice when someone was killed by equipment; one by a robot the other by a press. So I understand where management tends to go what seems like extremes.

Just so you know, Even though it may not have sounded like it, I actually agree, Seen a couple deaths and serious injuries also. I was very serious when I thanked the safety guy. The plant I worked in at the time was a very dangerous place if not for the safety department. Almost all serious accidents were caused by people defeating safety devices or doing something they were not supposed to do.

One place I worked, we caught a guy with a wooden stub fastened to his left leg using it to push a button on a two button press control so he could work faster operating the press. It was a Piece rate shop. He had quite an interesting rhythm operating the press with one hand and his leg.

jayrod7387

Member

OP

Safety cable def wont work with our safety standards today.

We have machines that have hard fencing with pivot points and wheels. They work, until they get hit by tow trucks/fork trucks.

We have a couple machines that use a retractable cable to keep 2 pivoting photoeyes aligned. They work, ok, BUT they really do not want us putting that on any more machines... I thought about doing the same thing with light curtains...

Thanks for all the input, I was just wondering if there was something on the market I wasnt aware of.

We have machines that have hard fencing with pivot points and wheels. They work, until they get hit by tow trucks/fork trucks.

We have a couple machines that use a retractable cable to keep 2 pivoting photoeyes aligned. They work, ok, BUT they really do not want us putting that on any more machines... I thought about doing the same thing with light curtains...

Thanks for all the input, I was just wondering if there was something on the market I wasnt aware of.

mendonsy

Member

Would a safety floor mat work?? Those are made in a lot of different sizes.

jstolaruk

Lifetime Supporting Member

Safety Mat or Scanner are very good choices. Scanners have some way down in prices due to competition.

Similar Topics

Upon entering our plant, we have a traffic light set up to indicate the safety level of our plant. Green means safe, yellow means non-recordable...

- Replies

- 5

- Views

- 2,574

I was just wondering if anyone had any experience with a VEGAPULS C 22 Radar sensor.

One of my customers got a cold call from one of there reps...

- Replies

- 10

- Views

- 2,797

Hello Collegues ! I am here today looking for help, i recently started a magister in controls and automation. I was thinking in doing an automated...

- Replies

- 7

- Views

- 1,987

We have AOIs for projects, which handle material dosing (by hand or by pipes and pumps), obviously they have comparison between setpoint and...

- Replies

- 50

- Views

- 14,205

Wizards,

With all the extra downtime this year, I have started guiding the newer maint staff through a test cell build.

It has been quite...

- Replies

- 1

- Views

- 1,364