Here is the situation:

I want a VFD to control a Fan motor - but I have a redundant fan that should not be used unless I am servicing the main Fan.

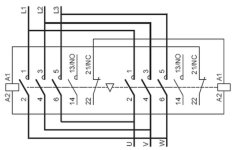

Is there a transfer switch of some type I can put between the VFD and the motor that would just toggle between the two motors - or would I be required to have a disconnect for each motor?

They should never both operate at the same time and I'm trying to think of the cleanest way to do this without having to provide a VFD for each motor.

Thanks for your opinions in advance!

I want a VFD to control a Fan motor - but I have a redundant fan that should not be used unless I am servicing the main Fan.

Is there a transfer switch of some type I can put between the VFD and the motor that would just toggle between the two motors - or would I be required to have a disconnect for each motor?

They should never both operate at the same time and I'm trying to think of the cleanest way to do this without having to provide a VFD for each motor.

Thanks for your opinions in advance!