ceilingwalker

Lifetime Supporting Member

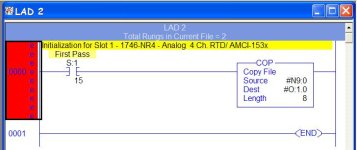

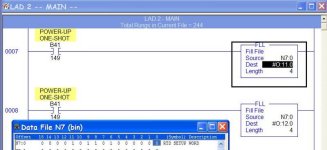

Good day all. I have an RTD module for a SLC500 5/03 that I can't get the temperature values to stop jumping from one temp to the next, on the HMI display. I don't know if there is a sampling rate or what exactly it is that I can do. The temp diplays 140-degrees F, for example, and looking at the display for only 5-seconds the temp will jump-up to 150, down to 120, then to 135, etc... . What can I do to get a more stable reading? Thank you.