Hello folks,

Hope everyone is doing well.

I am a beginner at working in analog signals with PLC

Analog module: 1769-IF4 ( 4 analog inputs )

PLC: ML 1500 LRP

I went through some older threads in the forum and the documentation, but I still struggled to get a correct image due to inexperience.

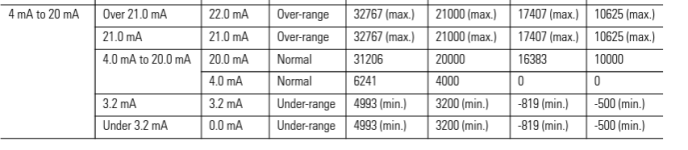

The analog output I am receiving from the loadcell weight indicator is 4-20ma.

ie,

0 kg ----> 4ma

45 kg----->20ma

On exactly 45kg, I want a bit to get energized and signal the robot to stop the cycle.

1. In RSlogix 500, when we select this analog module in i/o configuration, I can see a window containing the options to enable and a drop-down tab to select which type of input we are receiving. For me I should select the 4-20ma, right? Is there anything more to be done there?

2. In which terminals on the analog module should I connect the wires for 4-20ma input?

--------> I in 0 +

o/p from weight indicator |

--------> V/I in 0-

Is this the right way?

What about the analog comm? Leave it like that or need to short with V in 0+?

3. In the document, I read about an external supply, Do I need to use it only if I need to power up the indicator through the loop with the module? ( if the indicator has its own power supply, we do not need to add an extra supply to the analog module, right?

4. Please guide me with the programming to implement the requirement of energizing a bit at exact 45kg.

Which functions should I use in dealing with analog signals? (I never used the SCP, or compare functions, so please guide me through it) ?

Sorry for the long sequence of doubts.

please share your views and suggetions.

cheers

Hope everyone is doing well.

I am a beginner at working in analog signals with PLC

Analog module: 1769-IF4 ( 4 analog inputs )

PLC: ML 1500 LRP

I went through some older threads in the forum and the documentation, but I still struggled to get a correct image due to inexperience.

The analog output I am receiving from the loadcell weight indicator is 4-20ma.

ie,

0 kg ----> 4ma

45 kg----->20ma

On exactly 45kg, I want a bit to get energized and signal the robot to stop the cycle.

1. In RSlogix 500, when we select this analog module in i/o configuration, I can see a window containing the options to enable and a drop-down tab to select which type of input we are receiving. For me I should select the 4-20ma, right? Is there anything more to be done there?

2. In which terminals on the analog module should I connect the wires for 4-20ma input?

--------> I in 0 +

o/p from weight indicator |

--------> V/I in 0-

Is this the right way?

What about the analog comm? Leave it like that or need to short with V in 0+?

3. In the document, I read about an external supply, Do I need to use it only if I need to power up the indicator through the loop with the module? ( if the indicator has its own power supply, we do not need to add an extra supply to the analog module, right?

4. Please guide me with the programming to implement the requirement of energizing a bit at exact 45kg.

Which functions should I use in dealing with analog signals? (I never used the SCP, or compare functions, so please guide me through it) ?

Sorry for the long sequence of doubts.

please share your views and suggetions.

cheers