mattyg

Member

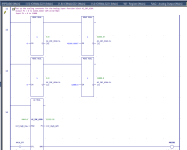

I'm pretty new to PLC's, so forgive me if I use the wrong terminology and whatnot. We have an issue at work where we have a flow meter that is scaled for 0 to 60 million gallons per day (MGD).

We simulated a 20 milliamp signal to verify our signal reaching our SCADA. When the 20 mA was applied, we got a flow reading of 47.184 MGD when 60 MGD was expected. In the logic when the 20 mA was applied, our analog value was correct at 32,000, so it seems like the problem is in the logic with the way the info i being stored in the register, maybe?

Can someone help me understand what is going on here and how I can get this to read correctly?

We simulated a 20 milliamp signal to verify our signal reaching our SCADA. When the 20 mA was applied, we got a flow reading of 47.184 MGD when 60 MGD was expected. In the logic when the 20 mA was applied, our analog value was correct at 32,000, so it seems like the problem is in the logic with the way the info i being stored in the register, maybe?

Can someone help me understand what is going on here and how I can get this to read correctly?