ivo.maenen

Member

- Join Date

- Nov 2003

- Posts

- 663

Here is a scenario in which I accidentally took down half a plant with.

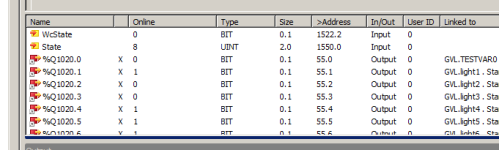

I was given a small window of time to shut everything down and add some IO points to a fairly large system. That program had a mix of wildcards and fixed addresses. I added some additional fixed addresses that happened to be higher than the auto generated addresses for the wild cards. TwinCAT regenerated and changed all of the auto generated addresses. I linked the new IO and restarted the system. As we tried to restart the system a large portion of the IO no longer worked. After a bit of time digging through, I discovered that re-addressing also deleted the links to all of those points.

That's the reason why you should use wildcard-adressing (according to Beckhoff).

When you insert an IO-card (see my attachment Beckhoff 2') the previous adressen can (not must) shift according to the type of card you insert afterwards.

A digital IO-card does not change the range of adresses, analog IO and other special cards do change the range of adresses also the range of the digital IO-card. That was the point I wanted to make with 'Beckhoff 1' and 'Beckhoff 2'.

Archie,

I did not realise that I had an Ethernet/IP-card inserted in that file. So it was not intended as a part of the question.

The question, or rather the remark what I wanted to make was that absolute adresses do change when you insert a not-digital-card afterwards.