mylespetro

Member

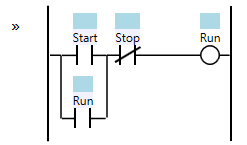

Looks to me like I3 (I believe, kind of hard to read) needs to go active to pull in Q2, which will then be "sealed in" by its own contact below I3. I only skimmed over the earlier posts so I'm not exactly sure what I3 is (high level?), but going on the red lines, it looks like it's active up to I3, and then the contact after it is highlighted red, which leads me to my conclusion that I3 didn't go active.