Hi!

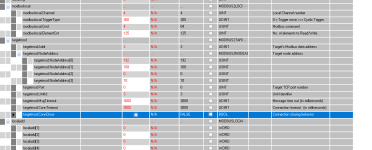

Last few I've been trying to send message from MicroLogix 1400 to Micro 850. Unfortunately every time I failed . Did someone tried that before? If yes can you please send me some literature where I can see how it's done or just try to explain me.

. Did someone tried that before? If yes can you please send me some literature where I can see how it's done or just try to explain me.

Thanks!

Last few I've been trying to send message from MicroLogix 1400 to Micro 850. Unfortunately every time I failed

Thanks!