alendi

Member

Hello everyone, stay safe at home, please.

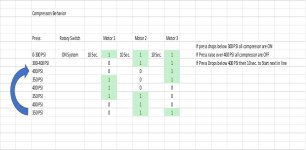

I'm looking for a solution in WPLSoft Delta in order to control 3 compressors boosters, attached you'll find a little true table showing compressors behavior, can anyone please help me with an idea how to proceed with WPLSoft?

I'll use a 4-20 ma pressure sensor, so PLC will use one analog input, also want to use a screen to show pressure value, any suggestion?

Thanks.

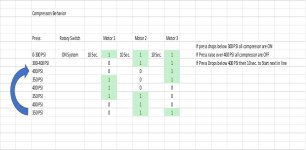

I'm looking for a solution in WPLSoft Delta in order to control 3 compressors boosters, attached you'll find a little true table showing compressors behavior, can anyone please help me with an idea how to proceed with WPLSoft?

I'll use a 4-20 ma pressure sensor, so PLC will use one analog input, also want to use a screen to show pressure value, any suggestion?

Thanks.