atoledob

Member

Hello all, this is my first time working with a PLC and dealing with hardware, so please have patience with me.

I have an electric rod-style actuator driven by a rotary servo motor and a servo drive. The actuator will exert force on a platform that can slide up and down. The goal is always to maintain constant force applied onto the platform. I connected a load cell in line with the direction of force transmission between the end of the actuator and the platform surface (i.e., the load cell is sandwiched between both surfaces). Additionally, I purchased a load cell amplifier that can condition the 2 mV/V load cell signal into 0-5 V/RS485 output. Ultimately, the goal is to achieve force control via the PID functions available within the S7-1200 PLC. At the end of a test, I want the actuator to return to the initial position and zero torque (tare).

Here are the specific products I am using:

The servo drive has options for Torque control mode, Torque/Speed control mode, and Torque/Position control mode. I believe that I can accomplish my tasks with just the Torque control mode. From the attachment, I plan to use the following digital inputs EM2 (forced stop - decelerates the motor to a stop), SON (servo on), RES (reset any alarms), RS1 (forward rotation), and RS2 (reverse rotation). I will have ALM (alerts a malfunction) and RD (alerts system is ready to operate) for the digital outputs. I bought all the necessary pushbuttons, selector switches, and e-stop for these digital inputs and outputs.

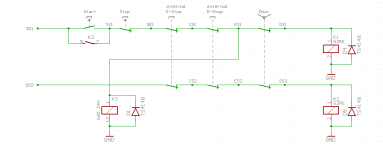

A 50-pin pigtail connector will interface the servo drive and PLC. I have provided my attempt at a wiring diagram. Some specific confusions/questions are:

My files are too big to upload, so please access the files on this Google Drive link.

I have an electric rod-style actuator driven by a rotary servo motor and a servo drive. The actuator will exert force on a platform that can slide up and down. The goal is always to maintain constant force applied onto the platform. I connected a load cell in line with the direction of force transmission between the end of the actuator and the platform surface (i.e., the load cell is sandwiched between both surfaces). Additionally, I purchased a load cell amplifier that can condition the 2 mV/V load cell signal into 0-5 V/RS485 output. Ultimately, the goal is to achieve force control via the PID functions available within the S7-1200 PLC. At the end of a test, I want the actuator to return to the initial position and zero torque (tare).

Here are the specific products I am using:

- Mitsubishi MR-J4-10A1-RJ servo drive

- Mitsubishi HG-KR13 servo motor

- Futek LSB201 load cell

- ATO Digital Load Cell Amplifier, Output 0-5V/RS485

- Norgren ELION Rod-Style Actuator

- Siemens CPU 1212C DC/DC/DC

The servo drive has options for Torque control mode, Torque/Speed control mode, and Torque/Position control mode. I believe that I can accomplish my tasks with just the Torque control mode. From the attachment, I plan to use the following digital inputs EM2 (forced stop - decelerates the motor to a stop), SON (servo on), RES (reset any alarms), RS1 (forward rotation), and RS2 (reverse rotation). I will have ALM (alerts a malfunction) and RD (alerts system is ready to operate) for the digital outputs. I bought all the necessary pushbuttons, selector switches, and e-stop for these digital inputs and outputs.

A 50-pin pigtail connector will interface the servo drive and PLC. I have provided my attempt at a wiring diagram. Some specific confusions/questions are:

- Should the e-stop be wired to a DI or 24 VDC? I’ve seen two wiring diagrams with both cases.

- My interpretation of shorting the unused analog inputs of the CPU is to jumper the inputs in X11 and connect them to 0 VDC. Is this correct? The CPU manual doesn’t have any details.

- I plan to power the CPU using a bulky lab-grade linear DC-regulated power supply (0-30 [VDC], 0-5 [A]). I calculated the power budget and found that I need a power output of >= 12 [W] and a current output >= 0.46 [A]. Should I stick with this PSU or use a switching power supply (maybe a class 2 PSU that plugs into a wall socket)?

- I’ve read in other discussion threads that I should not connect my load cell to the AI of the CPU because it only provides 10 bits which is far too low resolution. Would you recommend I purchase an extra AI signal board/module that allows for 12, 13, or even 16-bit capabilities?

- From the Torque wiring diagram, I think I also need to use the TC (analog torque command of +/- 8V) and wire it to an analog output of the CPU (I would have to purchase an AO module too). So, the load cell is connected to an AI and sends the PLC the force value. The PID loop uses the force setpoint to calculate the updated force value. Then, I will have to multiply this force value by an acting distance to get torque, and, lastly, scale it to +/- 8 V to send back to the servo drive. Am I thinking about this correctly?

My files are too big to upload, so please access the files on this Google Drive link.