MikeLB56

Member

Hi all,

I have an application where i need to sync up conveyors on an aerosol can line starting at the packaging portion of the line.

I have VFDs on the line but not at every motor. For instance, from the beginning, i start with 3 VFDs. i then get to 3 motors that the customer has asked not to automate. these run into, though and out of the labeling station. once onto the next station, the tipper (where they put on the little tip where the spay comes out)I have a VFD and into the next station the capper. after that i have 2 VFDs but again, the customer has asked to leave those operator controlled. once through there i have 6 VFDs through to the case packer and to the entrance of the case sealer where my control ends:

nc= no control

---[3vfds]---[3motors nc Labeler]---[TipperVFD]---[CapperVFD]---[staw&tape 2VFDs nc]---[6VFDs for Case Packer & Accum Table]-----[Box Sealer nc]----

At each station (labeler, tipper, capper, straw & tape, case packer, box sealer) there are photo eyes at each infeed and discharge. these act as start stop signals for the existing motor circuits.

the customer wants to increase their throughput as right now, the operators set the VFDs at "whatever speed the feel like" as my customer put it.

first, can i help the customer increase their throughput if i have motors in the middle of the line i cannot control or he would rather me not control?

second, how would i get feedback from the line as to how fast i should be running the VFDs? can i use the existing photoeyes some how in the program?

I will most likely being using analog signals into a CompactLogix but i am really looking for some concept help right now, not necessarily hardware.

any insight on this would be AWESOME!!!!!!!!!! THANKS!!!

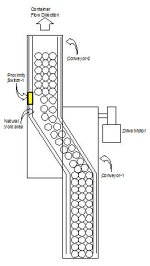

i hope my little picture helped up there if still totally lost i can scan something in!

I have an application where i need to sync up conveyors on an aerosol can line starting at the packaging portion of the line.

I have VFDs on the line but not at every motor. For instance, from the beginning, i start with 3 VFDs. i then get to 3 motors that the customer has asked not to automate. these run into, though and out of the labeling station. once onto the next station, the tipper (where they put on the little tip where the spay comes out)I have a VFD and into the next station the capper. after that i have 2 VFDs but again, the customer has asked to leave those operator controlled. once through there i have 6 VFDs through to the case packer and to the entrance of the case sealer where my control ends:

nc= no control

---[3vfds]---[3motors nc Labeler]---[TipperVFD]---[CapperVFD]---[staw&tape 2VFDs nc]---[6VFDs for Case Packer & Accum Table]-----[Box Sealer nc]----

At each station (labeler, tipper, capper, straw & tape, case packer, box sealer) there are photo eyes at each infeed and discharge. these act as start stop signals for the existing motor circuits.

the customer wants to increase their throughput as right now, the operators set the VFDs at "whatever speed the feel like" as my customer put it.

first, can i help the customer increase their throughput if i have motors in the middle of the line i cannot control or he would rather me not control?

second, how would i get feedback from the line as to how fast i should be running the VFDs? can i use the existing photoeyes some how in the program?

I will most likely being using analog signals into a CompactLogix but i am really looking for some concept help right now, not necessarily hardware.

any insight on this would be AWESOME!!!!!!!!!! THANKS!!!

i hope my little picture helped up there if still totally lost i can scan something in!