Good evening ,

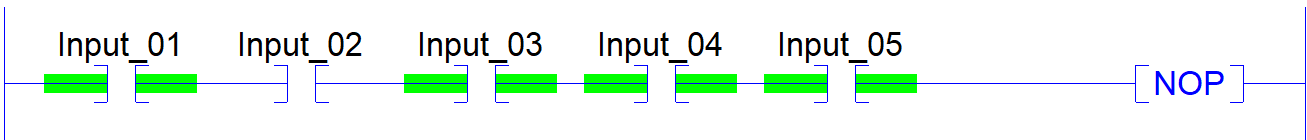

I was looking thru some Rockwell Automation programs , and took notice in some programs , UDT’s , AOI’s , etc. the NOP instruction .

Could you please explain what the purpose of a NOP instruction is , and why it would be used in a PLC program .

Thanks so much ,

I was looking thru some Rockwell Automation programs , and took notice in some programs , UDT’s , AOI’s , etc. the NOP instruction .

Could you please explain what the purpose of a NOP instruction is , and why it would be used in a PLC program .

Thanks so much ,