I think you need to give a little bit more information, for example, how many pulses per revolution of the pulley are you expecting, and how often do you need to determine the speed (note: slow pulses will mean a longer time to get a usable reading).

Think about what controls the speed of the pulley, is it driven off a VFD controller ?, maybe worth thinking of monitoring the VFD with analogue feedback of speed. etc.

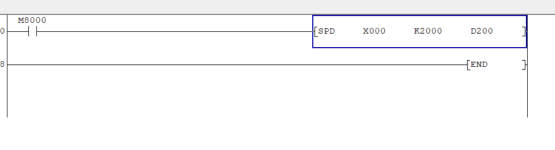

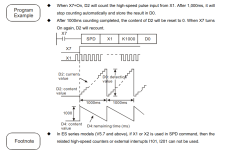

I believe the Delta PLC is actually based on the Mitsubishi FX range so it has high speed inputs to use on the high speed 32 bit counters, attached is a program for an FX3U (Delta are based on this), however, although the high speed counters are the same & the I/O i.e. X/Y, the special relay bits M8000 upwards are different for example the always on flag is M1000 instead of M8000 in delta, the 1 sec clock flag is M1013 instead of M8013

The counter is enabled when true you do not use the X0 (in this case in the program) as when the counter is enabled it automatically counts up C235 when X0 is false to true it is actually tied via hardware to the counter so cannot be used for anything else, you could change it to any of the first 8 inputs and use the counter tied to it i.e. C235 is X0 c236 is X1 etc.

See code attached, note this is just an idea, you may want to have a different sample time instead of one second you could use a timer that resets itself (oneshot), the principle is to count the pulses over a time period, store that into a register, then compare and if above a speed reset a bit or if below set a bit.

Here is a link to the manual

http://profsite.um.ac.ir/~shoraka/Delta PLC Applications Programmig.pdf