theColonel26

Lifetime Supporting Member

Rockwell CompactLogix or ControlLogix 5x70 or 5x80 series:

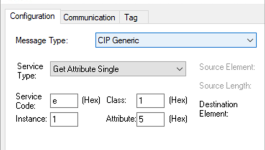

Is it possible to determine if a Remote PLC is in Program Mode from another PLC?

basically is there any tags I can read from another PLC using a MSG that will tell me if it is in program mode?

Bonus points for telling me if it is Running or Faulted too.

Is it possible to determine if a Remote PLC is in Program Mode from another PLC?

basically is there any tags I can read from another PLC using a MSG that will tell me if it is in program mode?

Bonus points for telling me if it is Running or Faulted too.