"even more so as it works better now than it did when running on the original plc/program"

How have you evaluated that your new program is more "betterah"

Through testing with the operator and my own experience of running it.

There were some odd occasions when the cycle would not finish correctly when the stop button was pressed, it might leave the last part uncut. It would also not stop at the correct point in the cycle when the printing foil ran out - it would merely stop, my version allows the whole cycle to complete before stopping.

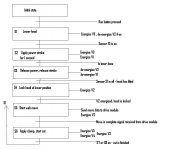

We also now have a better HMI where the user can select the type of job by name instead of having to enter cut specs manually - choosing the job now sets the feed length, amount of cuts required and the length of time the delivery belt runs for.

Not perfect yet but definitely better, plus the fact that we now have full control over the program