Well, clearly I have a lot more studying to do

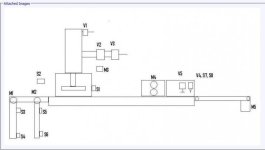

Take the relatively simple sequence in the PDF attached, it operates the cutter.

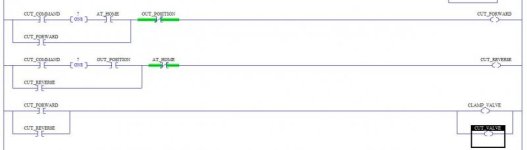

Requirements are that the clamp is on whenever the cutter is moving, the cutter is a linear slide and can cut both ways, when in auto it can stop at either end. It needs to accept a trigger from other procedures and set a "done" flag to indicate it has finished.

It sounded simple, wrote it down, run it through my head, all seemed ok.

In reality, the clamp only stayed on for the outward stroke and it never registered as having finished.

Hope that makes sense?

Maybe some kind soul could show me the error of my ways, maybe I am not thinking scan-cycle or something???

Many thanks

Dave

Take the relatively simple sequence in the PDF attached, it operates the cutter.

Requirements are that the clamp is on whenever the cutter is moving, the cutter is a linear slide and can cut both ways, when in auto it can stop at either end. It needs to accept a trigger from other procedures and set a "done" flag to indicate it has finished.

It sounded simple, wrote it down, run it through my head, all seemed ok.

In reality, the clamp only stayed on for the outward stroke and it never registered as having finished.

Hope that makes sense?

Maybe some kind soul could show me the error of my ways, maybe I am not thinking scan-cycle or something???

Many thanks

Dave