Mas01

Member

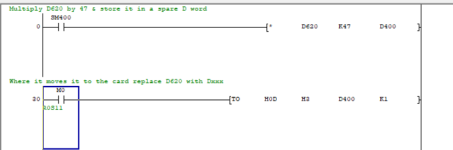

I've got a Q68DAIN (Mitsubishi Q series analogue output module). On the HMI, Basically on the screen, the user types in a value as a percentage (0-90) and this opens the water valve by the same amount. Basically, I want to multiply D620 (the value typed) by 47 before sending it out on the AO module.

I've tried doing the multiplication on the HMI (gt designer3) as a little script...the multiplication works and D620 is multiplied correctly, BUT it also multiplies the on-screen angular value by 47 which is clearly not what I want.

I prefer to do the multiplication in the code if possible...I just think it's cleaner like that... I'm not keen on "embedding" code in the HMI if it can be avoided.

Can anyone suggest what the code update should be?

Thanks

I've tried doing the multiplication on the HMI (gt designer3) as a little script...the multiplication works and D620 is multiplied correctly, BUT it also multiplies the on-screen angular value by 47 which is clearly not what I want.

I prefer to do the multiplication in the code if possible...I just think it's cleaner like that... I'm not keen on "embedding" code in the HMI if it can be avoided.

Can anyone suggest what the code update should be?

Thanks

Last edited: