milmat1

Member

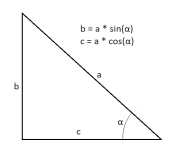

This application has a motor with encoder feedback that drives a linear actuator that moves in/out, and is at roughly 45 degs from horiz.

As the linear actuator moves in/out, it pushes a platform up and or down vertically, which is level with the horizontal. So movement is non-linear as related to the motor's rotation and linear actuator. Think of a motorized scissor lift.

If I know the counts at two points in the travel, and what they equal in vertical movement. How do I calculate the counts per inch of the lift. Or even revolutions per unit of vertical travel?

As the linear actuator moves in/out, it pushes a platform up and or down vertically, which is level with the horizontal. So movement is non-linear as related to the motor's rotation and linear actuator. Think of a motorized scissor lift.

If I know the counts at two points in the travel, and what they equal in vertical movement. How do I calculate the counts per inch of the lift. Or even revolutions per unit of vertical travel?