drbitboy

Lifetime Supporting Member

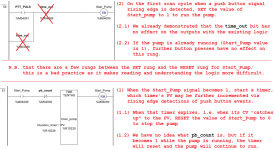

For example, consider these two rungs:

This is what I am mean when I say the rungs are not much different than random guesswork: they may work, but they are confusing.

- The value of time_out cannot be simultaneously

- BOTH 1 on the lower branch NOCON (Normally Open CONtact),

- AND 0 on the NCCON (Normally Closed CONtact) after the branches rejoin.,

- so the NOCON time_out and the lower branch can be removed, because it can never affect the output.

- Furthermore, the first rung shows that PTT_PULSE is a one-shot i.e.

- PTT_PULSE's value is 1 when the push button, I00013, has a rising edge,

- PTT_PULSE's value is 1 for at most one scan cycle

- For any scan when PTT_PULSE's value is 1,

- the value of I00013 must have been 0 on the previous scan cycle

- Therefore, if the PPT_PULSE value is 1, then the time_out bit's value cannot be 1 and must be 0,

- because the time_out value can be 1 only when the button is stuck

- i.e. when the value of I00013 has been 1 for at least the previous 15s of scan cycles,

- but we know that I00013 was 0 on the previous scan cycle.

- So if the PPT_PULSE value is 1, then

- The NOCON PTT_PULSE instruction must evaluate to TRUE,

- and the NCCON time_out instruction must evaluate to TRUE, because the time_out value is 0,

- And if the PPT_PULSE value is 0, then

- The NOCON PTT_PULSE instruction must evaluate to FALSE,

- so the value of time_out does not matter

- So the NCCON time_out instruction can be removed, because it can never affect the output.

- so the NCCON time_out instruction can be removed, because it can never affect the output.

This is what I am mean when I say the rungs are not much different than random guesswork: they may work, but they are confusing.