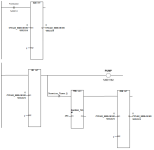

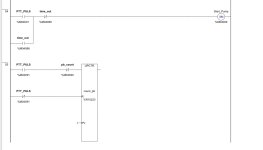

Simplify:Explanation: there is no need to use an extra rung testing for a value of 0 in the PUSH_BUTTON bit to reset the value of BUTTON_FAILURE to 0, because whenever the PUSH_BUTTON value is 0 the output rung of the timer will be FALSE, so we can use that instead.

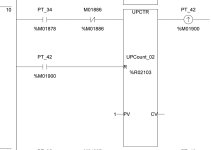

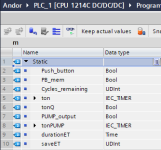

In other words, the desired behavior, that the BUTTON_FAILURE value transitions from 0 to 1 ("on") with a 15s (150ds) delay after the PUSH_BUTTON becomes and stays 1 (i.e. push button is "stuck"), is exactly what how the input and output rungs of the Timer ON-delay (TON) instruction behave.

TL;DR

If the timer has expired because the push button was stuck and the PUSH_BUTTON bit value has been 1 for at least 15s so the BUTTON_FAILURE value is 1, and then the push button becomes un-stuck so the PUSH_BUTTON value changes to 0, then the timer's output rung will change from TRUE to FALSE, and the coil will write a value of 0 to BUTTON_FAILURE.

Also, if the timer begins timing but has not yet expired, then the timer's output rung will be FALSE, so the value of BUTTON_FAILURE will also be 0.

Only when the timer has expired, because the push button has been stuck for at least 15s, will the timer's output rung become TRUE, which will cause the coil to write a value of 1 to BUTTON_FAILURE.

The key point to remember is that a Coil instruction always writes something, either 1 or 0, to the value of its operand BUTTON_FAILURE, even if value being written is the same as the value of the operand before the Coil instruction executes.

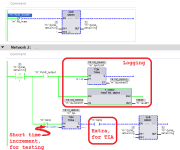

sorry I forgot to mention that other programs are running in addition to this, and that if the push button is stuck, a message is sent to the HMI as a fault and everything is stopped for safety. something has gone wrong with the push button in the past.