isaacchandler99

Member

-Please see attached code samples-

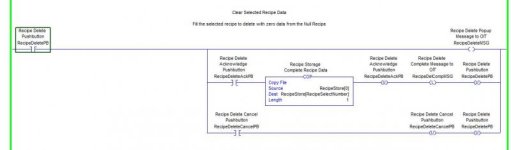

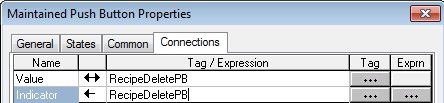

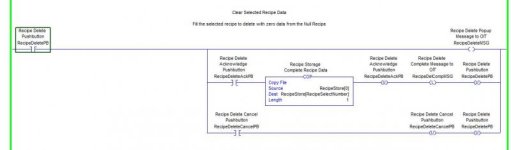

On my HMI I have a maintained pushbutton that toggles the tag "RecipeDeletePB". When this is pressed, it toggles the bit "RecipeDeleteMSG" which controls the visibility animation of a small popup window with yes and no maintained pushbuttons. These pushbuttons toggle the tags "RecipeDeleteAckPB" and "RecipeDeleteCancelPB" respectively and so either initiate the copy instruction or close the popup window. For some reason, I have to press the PB that toggles RecipeDeletePB twice EVERY time. I changed the code to the second set of rungs and now it works. I just can't figure out why. Any ideas? Also, it does the same thing on the HMI or running the client on my laptop. I am using RSlogix 5000 ver. 20.1 and FactoryTalk View ME 7.0

On my HMI I have a maintained pushbutton that toggles the tag "RecipeDeletePB". When this is pressed, it toggles the bit "RecipeDeleteMSG" which controls the visibility animation of a small popup window with yes and no maintained pushbuttons. These pushbuttons toggle the tags "RecipeDeleteAckPB" and "RecipeDeleteCancelPB" respectively and so either initiate the copy instruction or close the popup window. For some reason, I have to press the PB that toggles RecipeDeletePB twice EVERY time. I changed the code to the second set of rungs and now it works. I just can't figure out why. Any ideas? Also, it does the same thing on the HMI or running the client on my laptop. I am using RSlogix 5000 ver. 20.1 and FactoryTalk View ME 7.0