Mas01

Member

Sorry for the basic question:

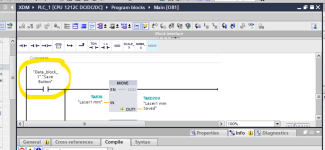

On my HMI, I've created a button labelled SAVE to save the current values (distances in mm). It's not linked to any Boolean in the code yet.

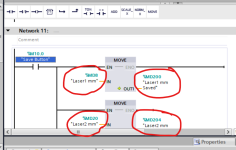

When the screen button SAVE is pressed, the values of certain tags are saved.

Basic question: What's the best way to define this Boolean in terms of its address? Am I free to call it M0.0 in the code or should I call it something else?

EDIT: I think I heard something like using M-bits was not good practice?

Hope that makes sense. Thanks

On my HMI, I've created a button labelled SAVE to save the current values (distances in mm). It's not linked to any Boolean in the code yet.

When the screen button SAVE is pressed, the values of certain tags are saved.

Basic question: What's the best way to define this Boolean in terms of its address? Am I free to call it M0.0 in the code or should I call it something else?

EDIT: I think I heard something like using M-bits was not good practice?

Hope that makes sense. Thanks

Last edited: