GRANDMAST3R5

Member

Hi everyone,

This is my first time posting, so please forgive any omissions or mistakes.

I am attempting to control the velocity of a stepper motor to TEST my PID controller before applying it to a real system (on the real system, I am controlling a loading rate, measured in N/min, not velocity). The real system is delicate, and as I'm a beginner, I want to ensure that my PID controller operates effectively when it is decoupled.

I am trying to convert the encoder A input pulses to RPM for my feedback signal. Since the real system will be operating at speeds < 1 RPM, I have opted for a pulse timing method instead of attempting to measure a change in position. This decision was made because interrupt-based methods don't seem to be accurate at low speeds.

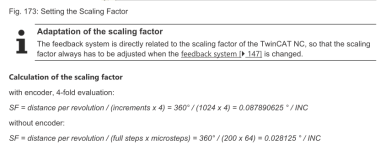

I am using an AS2023-0J10 Stepper Motor in conjunction with an EL7047 driver card. The stepper motor has an incremental encoder capable of providing 1024 increments per revolution. However, as it operates in quadrature mode, this effectively translates to 4096 increments per revolution. Nonetheless, tracking the A input pulse still results in 1024 increments, as it only signifies one of the four states in quadrature mode.

Could anyone provide guidance on how to go about calculating RPM from encoder pulses in TwinCAT3?

This is my first time posting, so please forgive any omissions or mistakes.

I am attempting to control the velocity of a stepper motor to TEST my PID controller before applying it to a real system (on the real system, I am controlling a loading rate, measured in N/min, not velocity). The real system is delicate, and as I'm a beginner, I want to ensure that my PID controller operates effectively when it is decoupled.

I am trying to convert the encoder A input pulses to RPM for my feedback signal. Since the real system will be operating at speeds < 1 RPM, I have opted for a pulse timing method instead of attempting to measure a change in position. This decision was made because interrupt-based methods don't seem to be accurate at low speeds.

I am using an AS2023-0J10 Stepper Motor in conjunction with an EL7047 driver card. The stepper motor has an incremental encoder capable of providing 1024 increments per revolution. However, as it operates in quadrature mode, this effectively translates to 4096 increments per revolution. Nonetheless, tracking the A input pulse still results in 1024 increments, as it only signifies one of the four states in quadrature mode.

Could anyone provide guidance on how to go about calculating RPM from encoder pulses in TwinCAT3?