myusername

Member

Hi, how do i include the fractional part of the position I set for encoder? I have an Omron PLC and using cx programmer. I need to command my servo (from HMI number input) to move to a certain position.

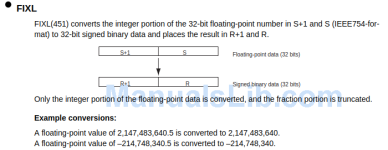

Now using a manual computation, my servo is supposed to move 95.65mm, however, using my plc program, the resulting position doesn't include the 0.65. I used the FIXL instruction to convert my result from float to 32 bit and it removed the fractional part of the value.

Thank you very much!

Now using a manual computation, my servo is supposed to move 95.65mm, however, using my plc program, the resulting position doesn't include the 0.65. I used the FIXL instruction to convert my result from float to 32 bit and it removed the fractional part of the value.

Thank you very much!