Hello,

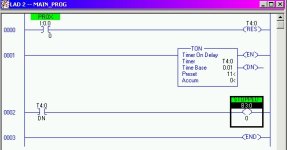

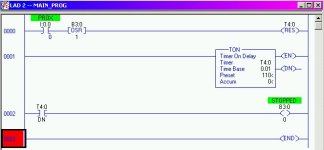

I am trying to use a prox switch to indicate when a spindle has stopped rotating. The prox is made by a "vane" that is on the spindle. My thought was to have a timer (TON) that has a time base just higher than the time required to make one full revolution of the spindle. As long as the spindle is rotating the prox would signal the timer to reset. Once the spindle stalls, a timer done bit would become true, and the program would execute the next step in the process. I am trying to use the prox input, to output a reset of the timer. Would anyone be inclined to tell me if this is an appropriate method, or maybe some other more straightforward way to do this is available? As of now the timer never starts timing, I think this is because the prox is being used to start the timer, and the next rung uses the prox to reset the timer. Any suggestions would be greatly appreciated.

Thanks,

Matt

p.s. the spindle speed is approximatly 60 rpm

MicroLogix 1000

DC inputs Relay Outputs

I am trying to use a prox switch to indicate when a spindle has stopped rotating. The prox is made by a "vane" that is on the spindle. My thought was to have a timer (TON) that has a time base just higher than the time required to make one full revolution of the spindle. As long as the spindle is rotating the prox would signal the timer to reset. Once the spindle stalls, a timer done bit would become true, and the program would execute the next step in the process. I am trying to use the prox input, to output a reset of the timer. Would anyone be inclined to tell me if this is an appropriate method, or maybe some other more straightforward way to do this is available? As of now the timer never starts timing, I think this is because the prox is being used to start the timer, and the next rung uses the prox to reset the timer. Any suggestions would be greatly appreciated.

Thanks,

Matt

p.s. the spindle speed is approximatly 60 rpm

MicroLogix 1000

DC inputs Relay Outputs