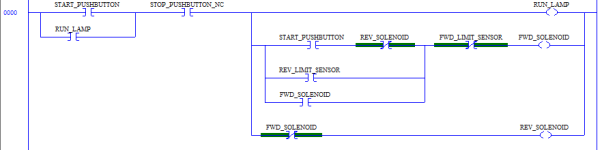

Hello all, I am a beginner and am requesting some help. I have been tasked with a program in ladder logic where once the start button is pressed, the pneumatic solenoid must fully extend, then fully retract, forever, until the stop button is pushed, and the ON light is present the entire time its running.

There is a sensor that lets you know once it has reached full extension and likewise for retraction.

There are two issues I am facing in my various attempts at this program, one being both outputs come on at the same times, making the cylinder extend/retract slowly. If I correct that, the other issue is if the piston is in the middle, and neither sensor is activated letting the program know if its in the extended or retracted position, it will not start. So it needs to be able to start from any position.

I have spent a long time on this, and really hate to ask for assistance but I need to understand what I am doing wrong so I can become better. I appreciate it so much thank you all.

There is a sensor that lets you know once it has reached full extension and likewise for retraction.

There are two issues I am facing in my various attempts at this program, one being both outputs come on at the same times, making the cylinder extend/retract slowly. If I correct that, the other issue is if the piston is in the middle, and neither sensor is activated letting the program know if its in the extended or retracted position, it will not start. So it needs to be able to start from any position.

I have spent a long time on this, and really hate to ask for assistance but I need to understand what I am doing wrong so I can become better. I appreciate it so much thank you all.