drbitboy

Lifetime Supporting Member

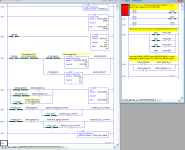

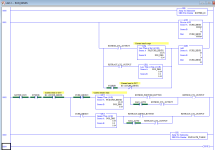

Also, since, per main.pdf, subroutine Position1 is only called if boolean Pos1 is 1, then why are there redundant (i.e. unnecessary) Normally Open contacts testing Pos1 in subroutine Position1?

Same query for boolean SYSenb?

Also, what do B01 and Z01 do?

Same query for boolean SYSenb?

Also, what do B01 and Z01 do?

Last edited: