Hi

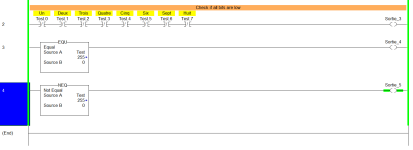

I did not find the instruction. I am a very part time user of Rockwell soft.

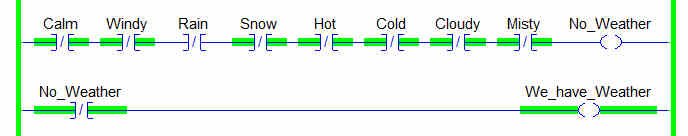

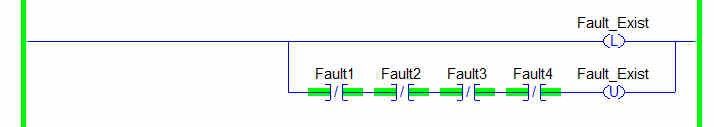

I am looking for the same "NOT" function that you can use in Schneider and Siemens software.

When you have a lot of parallel bits that you want to sum it's much more readable to write them with a NOT than putting them in parallel.

Like this exemple in Schneider's soft.

I did not find the instruction. I am a very part time user of Rockwell soft.

I am looking for the same "NOT" function that you can use in Schneider and Siemens software.

When you have a lot of parallel bits that you want to sum it's much more readable to write them with a NOT than putting them in parallel.

Like this exemple in Schneider's soft.