rejoe.koshy

Member

Hey Guys,

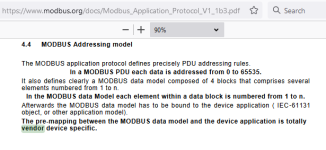

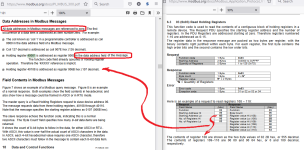

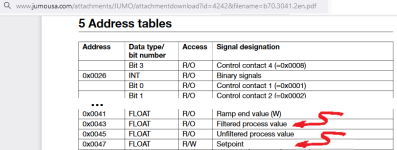

I am struggling to read data from a "JUMO" make controller using modbus RTU with MLX1400. The communication between the devices has been established but the data received is not in line with the actual values displayed on the temperature controller (JUMO).I am assuming its got something to do with the address (registers) of these values .I am trying to read the process value and set point.

Can anyone who has worked with the controller help?

I am struggling to read data from a "JUMO" make controller using modbus RTU with MLX1400. The communication between the devices has been established but the data received is not in line with the actual values displayed on the temperature controller (JUMO).I am assuming its got something to do with the address (registers) of these values .I am trying to read the process value and set point.

Can anyone who has worked with the controller help?