AutomationTechBrian

Lifetime Supporting Member

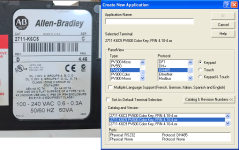

I had another legacy HMI replacement fall in my lap. A good customer of mine lost the program out of an old PanelView 600 (I'll attach some photos). I don't know why the program would be lost on this PV, but fortunately there is a twin machine (fraternal twin, maybe) right next to it that has a slightly newer series PV 600. The program that should be the same, or at least close enough to work with. I suspect I'm going to see more and more of this, and I don't have experience determining the best solution to replacing this HMI. I see in Google there are refurbished PVs available. Probably the easiest thing would be to find a replacement that matches the newer PV, so I could upload the file (PanelBuilder 32, I believe) and download into the refurbished HMI. Are there other (quick) solutions I should consider? It communicates with a SLC 5/04 over the serial port. I don't know what I don't know about this, and I'd like to get your thoughts & experience on this. Any quirks, or "gotchas"?

The affected Panelview:

ERROR: 1110, No valid Application.

CAT: 2711-K6C5, SER B

REV B, FRN 3.13

The twin PV with a program:

2711-K6C5, SER C

REV D, FRN 4.46

Thanks!

The affected Panelview:

ERROR: 1110, No valid Application.

CAT: 2711-K6C5, SER B

REV B, FRN 3.13

The twin PV with a program:

2711-K6C5, SER C

REV D, FRN 4.46

Thanks!