J. Feldman

Member

Hey All,

I have a newbie question I'm hoping to get help with.

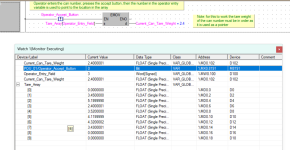

I am developing a controls system for a Loss-in-weight feeding system. The operators load a can of materials and it is fed through a screener. We have 14 of these stations. We reuse the same set of cans, but they are all bespoke with varying weights. I wanted to implement a system to store their tare weights so the LIW feeding is as accurate as possible. Each can has an assigned number engraved on it, and we have a list of their Tare weights, but the operators don't have access to that info. I wanted to add an input to the HMI where operators just punch in the can number, and the PLC adjusts the tare weight to the correct value. I have a common "Station" screen built in FactoryTalk, with parameters for each station (Can #, feed rate setpoint/actual, TARE weight, etc.). Here-in lies my question:

What is the easiest way to achieve this? I know I could have the logic check the can number assigned to the station, and then move the correct weight into the TARE value for that station; but the only way I know how to do this would require essentially 121 rungs of logic (for each can) and then copying that 14 times, for each station. There must be a simpler way to accomplish this without taking 1694 rungs, right?

Thank you in advance for your help!

I have a newbie question I'm hoping to get help with.

I am developing a controls system for a Loss-in-weight feeding system. The operators load a can of materials and it is fed through a screener. We have 14 of these stations. We reuse the same set of cans, but they are all bespoke with varying weights. I wanted to implement a system to store their tare weights so the LIW feeding is as accurate as possible. Each can has an assigned number engraved on it, and we have a list of their Tare weights, but the operators don't have access to that info. I wanted to add an input to the HMI where operators just punch in the can number, and the PLC adjusts the tare weight to the correct value. I have a common "Station" screen built in FactoryTalk, with parameters for each station (Can #, feed rate setpoint/actual, TARE weight, etc.). Here-in lies my question:

What is the easiest way to achieve this? I know I could have the logic check the can number assigned to the station, and then move the correct weight into the TARE value for that station; but the only way I know how to do this would require essentially 121 rungs of logic (for each can) and then copying that 14 times, for each station. There must be a simpler way to accomplish this without taking 1694 rungs, right?

Thank you in advance for your help!