Mas01

Member

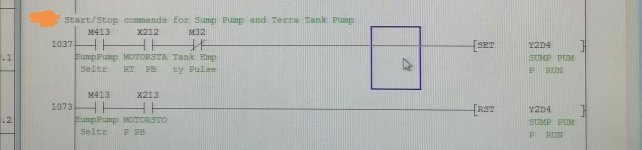

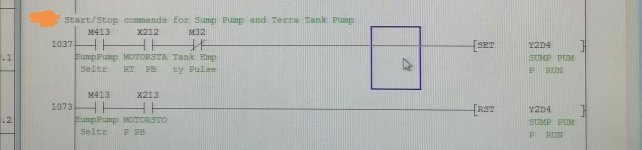

We've got a sump pump which is switched on/off at the HMI by clicking a button on the screen then a physical pushbutton on a console, using this code. The code works fine for starting/stopping the pump (see Step 1034/1070)

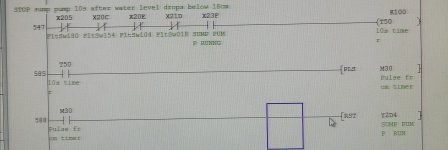

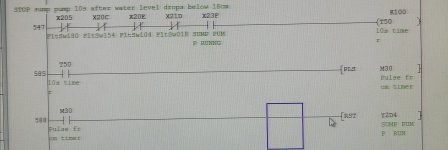

We've also got another step in the code where the pump will automatically turn off if the water level is below 18cm (to prevent damaging the pump). See step 547 onwards.

HOWEVER, as the code stands, once the pump turns off due to the low water level, it does not turn back on once the water level starts rising again (and this is a requirement)

I'm not sure how to include the "low water condition" into the start/stop logic so that there is only one SET and only one RST instruction for this pump.

Can anyone help? Thanks in advance.

We've also got another step in the code where the pump will automatically turn off if the water level is below 18cm (to prevent damaging the pump). See step 547 onwards.

HOWEVER, as the code stands, once the pump turns off due to the low water level, it does not turn back on once the water level starts rising again (and this is a requirement)

I'm not sure how to include the "low water condition" into the start/stop logic so that there is only one SET and only one RST instruction for this pump.

Can anyone help? Thanks in advance.