Hi All, apologies I don't have access to a remote IO module to test this out.

I have a number of remote IO blocks, each with approx 8 IO cards installed.

I wanto throw an alarm if an error is detected on any of the cards.

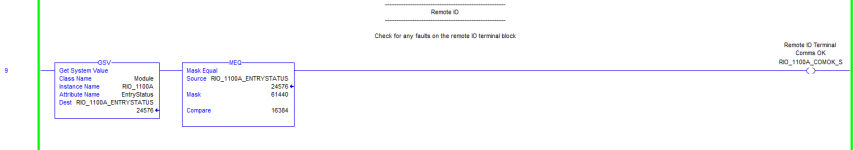

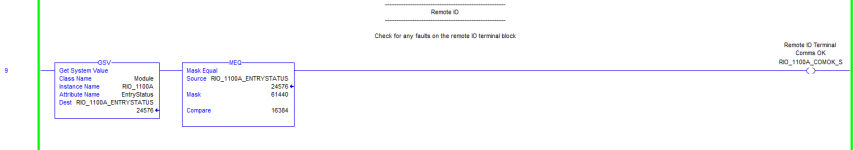

Usually I have used the GSV.Module.RIO_1100A.EntryStatus, and compared it to 16#4000 (16384 = RUNNING). - see attached screeenshot.

If I wanted to check for a fault on any of the attached cards, can I find this anywhere in the AENTR Module class? Or will i have to use GetSysValue on each of the cards individually?

Cheers!

I have a number of remote IO blocks, each with approx 8 IO cards installed.

I wanto throw an alarm if an error is detected on any of the cards.

Usually I have used the GSV.Module.RIO_1100A.EntryStatus, and compared it to 16#4000 (16384 = RUNNING). - see attached screeenshot.

If I wanted to check for a fault on any of the attached cards, can I find this anywhere in the AENTR Module class? Or will i have to use GetSysValue on each of the cards individually?

Cheers!