celichi

Lifetime Supporting Member

Hello All,

I hope we are all doing great and have a healthy and happy 2023!!

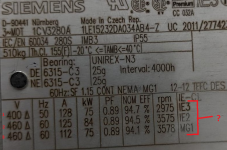

I was wondering if anyone could help me decode this Motor Name Plate.

I am trying to setup the 753 Parameters as part of the Quick Start / Static Tune.

The NP has 3 rows, and I am not sure which values to use.

Why are there 3 rows, and how do I know which one is correct...?

Kind regards - Paul

I hope we are all doing great and have a healthy and happy 2023!!

I was wondering if anyone could help me decode this Motor Name Plate.

I am trying to setup the 753 Parameters as part of the Quick Start / Static Tune.

The NP has 3 rows, and I am not sure which values to use.

Why are there 3 rows, and how do I know which one is correct...?

Kind regards - Paul