Ones_Zeros

Member

Hello

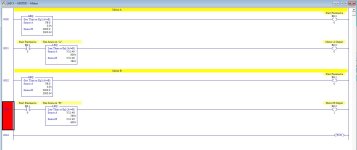

I was needing some guidance on how to incorporate a high flow value of 14000 into the logic below to start the second motor.

What I have is the following

1. A run permissive bit (B9:1/0) at a flow of 2000

2. Then the logix compares the run hours to determine which motor has the lowest hours to run.

3. Once its determined which motor to start by the 2000 flow and smallest run hours. Then I'd like to add to the logix to where if the same flow gets to 14000 I'd like to start the second motor.

how would i add this logix to the attached screen shot?

I appreciate the help

thanks,

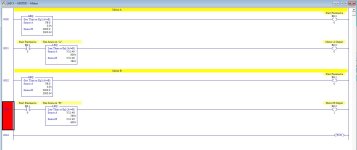

I was needing some guidance on how to incorporate a high flow value of 14000 into the logic below to start the second motor.

What I have is the following

1. A run permissive bit (B9:1/0) at a flow of 2000

2. Then the logix compares the run hours to determine which motor has the lowest hours to run.

3. Once its determined which motor to start by the 2000 flow and smallest run hours. Then I'd like to add to the logix to where if the same flow gets to 14000 I'd like to start the second motor.

how would i add this logix to the attached screen shot?

I appreciate the help

thanks,