sparkytex

Lifetime Supporting Member

hello again,

lets disregard that last thread I posted about the Panel Builder 1200. What I really need help with is some logic design. Here's what's going on, Our bleach Screen room has a "dump flush cycle" 1-2 times per 12 hour shift initiated by the operator on the HMI with the "Dump" button icon. They keep log of the times of the last 4 dump flush's which they take off of the HMI indication. Since the HMI is an old Panel view 1200 and I'm replacing it with a touchscreen and Wonderware I need to mimic this. Here's what I need to do:

I need to create logic to Keep track of the times of the last 4 dump flush cycles and display it onto Wonderware in real time. The old display looked like this

1.) Last dump cycle - 7:30

2.) 2nd Last dump cycle - 18:06

3.) 3rd Last dump cycle - 12:01

4.) 4th Last dump cycle - 17:44

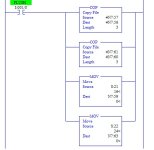

it constantly cycles down the integer value from "Last" to "4th Last" every time you press the "dump" button. I tried doing this with a FFL-FIFO but just couldn't quite figure it out. I'd be much appreciated if one of the Wiz's on this site could help me design this for RSLogix 5.

Thanks, Tex

lets disregard that last thread I posted about the Panel Builder 1200. What I really need help with is some logic design. Here's what's going on, Our bleach Screen room has a "dump flush cycle" 1-2 times per 12 hour shift initiated by the operator on the HMI with the "Dump" button icon. They keep log of the times of the last 4 dump flush's which they take off of the HMI indication. Since the HMI is an old Panel view 1200 and I'm replacing it with a touchscreen and Wonderware I need to mimic this. Here's what I need to do:

I need to create logic to Keep track of the times of the last 4 dump flush cycles and display it onto Wonderware in real time. The old display looked like this

1.) Last dump cycle - 7:30

2.) 2nd Last dump cycle - 18:06

3.) 3rd Last dump cycle - 12:01

4.) 4th Last dump cycle - 17:44

it constantly cycles down the integer value from "Last" to "4th Last" every time you press the "dump" button. I tried doing this with a FFL-FIFO but just couldn't quite figure it out. I'd be much appreciated if one of the Wiz's on this site could help me design this for RSLogix 5.

Thanks, Tex