@Pandiani: I read the article. It is very interesting. But my problem is how to use it in a PLC? I am looking forward to that example with a PID controller combined with the Smith predictor.

Is it possible to do moddeling without step response in a PLC? Just by looking at the CO, PV & SP.

I really think you should take more time to study and understand how FOPDT is implemented. Then you would probably figure it out how to make the Smith predictor implementation in the PLC.

Anyway just for the exercise and education ONLY, I have attached the source code as well as an example of OB35 calls. Like I said, it is only for demonstration purpose, made to be used in PLCSIM and not in the real world. However theory works and it can be used in the real world but only after you have a full understanding what is going on and of course use it at your own risk.

There are three files attached:

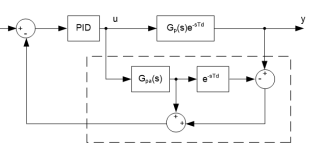

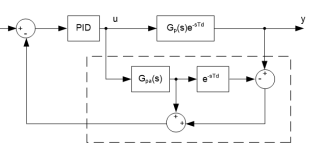

1. The structure of the Smith predictor block diagram that needs to be implemented and simulated in the PLC. In reality you'll not have FOPDT structure in your PLC program, that would be a real world system you're trying to control.

2. The source code of the Smith predictor implementation

3. An example of OB35 call with actual built in PID from the standard library.

Use it to learn it. It is made for educational purpose only. Don't trust this code in real world environment.

I hope you'll have fun and learn something useful.